News Center

An Oiling System Manufacturer Integrating Design, Production And Sales, With Its Own Brand TRIBOS, Has Been Committed To The Development And Production Of Precision Automatic Oiling Devices For Stamping Processing For Many Years

Oiling device: What are the functional characteristics of the visual oiling device?

Release time:

2021-02-09 12:06

Source:

www.tribos.cn

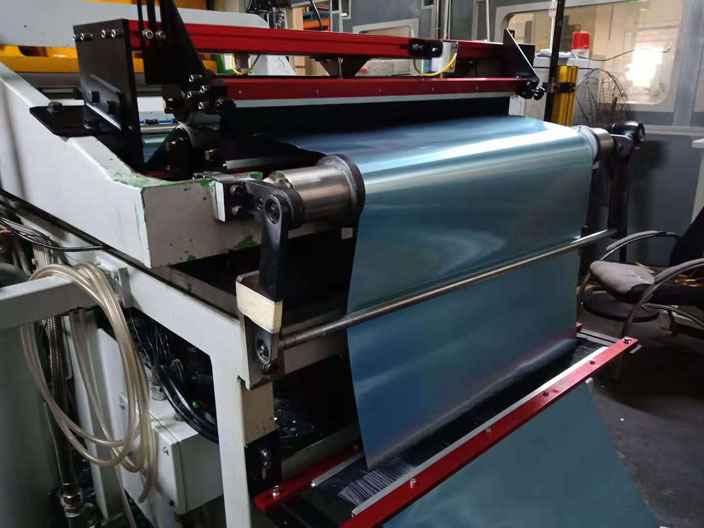

The visual oiling device can place the workpiece directly on the conveyor, or feed it indirectly through other auxiliary materials such as inspection tables and workbenches, and can also be connected to other conveying equipment. The product makes a pendulum movement in the rotating cage, and by rotating the cage, the product can be pushed forward all the way to the unloading carrier. The products on the stainless steel belt are conveyed to the inlet through the chain drive and slide into the receiving box. The atomized particles are fine and uniform. Powered by compressed filtered air and hydraulic pump pressure, the liquid and gas are evenly mixed through the air atomizing nozzle, and fine droplets are sprayed into the working space to cover the product finely and evenly with a soft film oil layer. The atomized oiling medium is precisely filtered. The liquid pressure generated by the oil pump is driven into the micro-atomization nozzle to produce very fine droplets, thus obtaining a uniform wet mist oiling effect.

The nozzles of the visual oiling device are not easy to be clogged, which prolongs the service life. The variable frequency motor can control the propulsion speed, adjust the oiling length and efficiency, and regulate the oiling thickness through the inverter with infinitely variable speed within a certain range. The fan strongly circulates to suck in the oil mist, and through the filtration of the filter sponge at the lower part of the machine base and the filtration of the carbon cartridge at the outlet, the excess oil mist overflowing from the box is processed into oil liquid, which can be recycled and is non-polluting to the working environment and reduces energy consumption. It can be connected, cleaned, dried and coated into one integrated machine with high working efficiency.

The cleaning work of the visual oiling device includes: (1) removing metal debris and debris falling into the oiling chamber. (2) Scraping off the oil stains on the insulation guide and oil tank with the oil scraping brush. When cleaning the oiling chamber, strictly follow the following steps: (1) cut off the high-voltage power supply, remove the key of the high-voltage power switch and confirm that the pointer of the high-voltage meter is zero; (2) confirm that the red light of the high-voltage alarm is off and the green light is on; (3) open the door of the oiling chamber and then touch the oiling knife beam with the grounding rod; (4) if necessary, remove the oiling knife beam inside the oiling chamber. Therefore, pull out the high-voltage cable from the jack, pull out the retaining pin, and then move the refueling knife beam out of the refueling chamber. (5) Carry out cleaning work. If the knife beam cutter after oiling is polluted by dirt or waste edge, it will affect the quality of oiling and must be dealt with in time, which can be dealt with as follows: (1) When the pollution is not serious, the knife beam can be flushed with high flow oil. (2) When the above methods are ineffective, cut off the high pressure, open the door of the oiling room, discharge with a grounding rod, and gently wipe away the dirt stained on the knife mouth with a rubber or sponge brush along the direction of the knife mouth. Take special care not to injure the blade of the oiling device. Machine vision can improve the production line and increase the quality and output of products.